Cat:Products

Continuous tubing, also known as flexible tubing or flexible tubing, is widely used in the fields of well workover, logging and drilling, etc. Its pro...

See Details

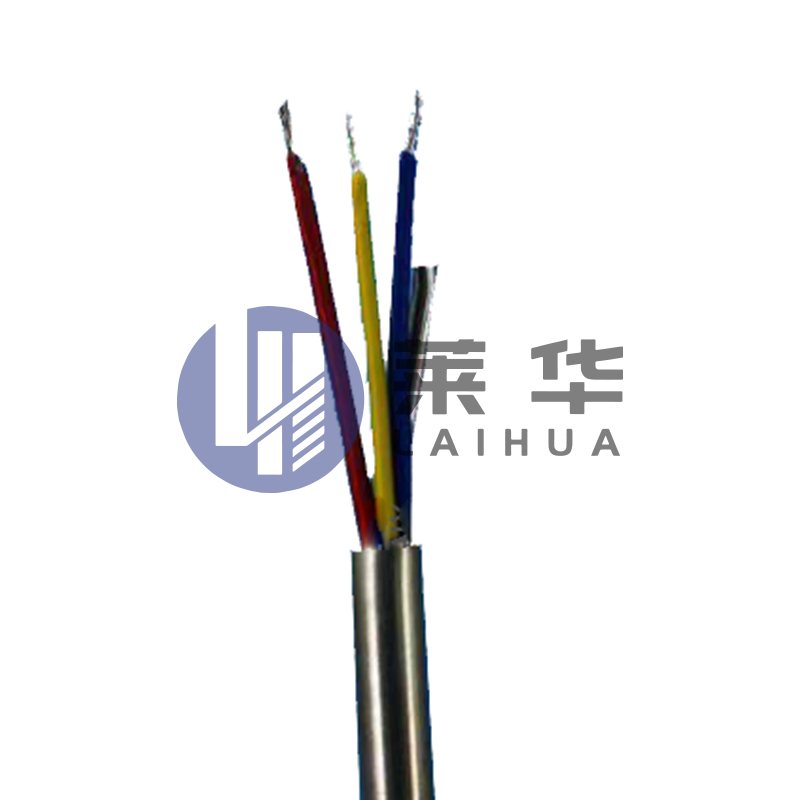

The minimum bending radius is one of the most critical specifications to consider when selecting a test cable, especially in environments that demand high precision and reliability, such as testing labs, industrial setups, and even oil fields. For stainless steel fibre optic test cables, this characteristic plays a pivotal role in ensuring that the cable functions optimally while maintaining the integrity of signal transmission. The minimum bending radius refers to the smallest radius a cable can be bent without damaging the fiber optic core or the surrounding materials, thus ensuring that it retains its transmission quality and mechanical strength.

In practice, the minimum bending radius for a stainless steel fibre optic test cable is typically governed by a combination of the optical fiber's properties and the protective stainless steel layer that surrounds it. The stainless steel exterior provides robust mechanical protection, offering high tensile and compressive strengths. However, this durability does not mean the cable can bend freely without consequences. Bending the cable too sharply can cause the optical fibers inside to compress, resulting in increased signal attenuation, potential breakage, or degradation in performance. This is especially critical in applications requiring highly accurate data transmission, such as performance testing of electronic equipment, communication systems, and oilfield pressure measurements, where even slight losses in signal integrity could compromise the test results.

The typical bending radius for a stainless steel fibre optic test cable is usually specified as a multiple of the cable's outer diameter (often around 10-15 times the diameter), but this can vary depending on the manufacturer and the type of optical fiber used. For example, cables designed for more rugged environments, such as those used in industrial testing or field-based applications, may have slightly more flexibility in their bending capabilities, but they are still generally subject to limitations. These cables are engineered to withstand harsh environments, with the stainless steel providing resistance to wear, corrosion, and mechanical stress, yet their performance can still be significantly impacted if bent beyond the recommended radius.

Understanding how the minimum bending radius affects installations is crucial, especially when working in tight spaces or during complex cable routing. For example, in factory production lines, where cables need to follow specific paths through machinery or around corners, improper handling could lead to costly downtime, as damaged cables would need to be replaced or repaired. Similarly, in oilfield applications where the cables are often exposed to extreme temperature variations, pressure, and physical wear, bending the cable too sharply could reduce its lifespan or cause failure during critical testing. This is why it's essential to always consider the space available and route the cables accordingly, ensuring that they can bend within the permissible radius without compromising performance.

Moreover, cables with more stringent bending requirements will often require careful installation planning. This might involve using cable guides, protective conduits, or additional supports to ensure the cables are laid out in a manner that does not force them into sharp bends. In scenarios where flexibility is more important than absolute bending limits, some cables may be designed to have more lenient bend radius specifications, though this often comes at the cost of slightly reduced mechanical protection. In most cases, ensuring the right installation conditions can prevent issues like signal loss, fiber damage, and long-term reliability problems that can arise from improper cable handling.

The flexibility of a stainless steel fibre optic test cable also means that, while it can be used in some tight spaces, it requires a balance between mechanical durability and signal integrity. For example, in highly dynamic testing environments such as those found in electronics testing or scientific laboratories, cables often need to be able to handle both constant movement and tight space installations. In such situations, selecting a cable with an appropriate bend radius can ensure that the test setup remains both efficient and reliable, without sacrificing the quality of the results.

Contact Us