Quality and sealing performance of stainless steel ferrule joints from Jiangsu Laihua Petroleum Equipment Co., Ltd.

Jiangsu Laihua Petroleum Equipment Co., Ltd., based in Hai'an City, Jiangsu Province, is a leading manufacturer specializing in the production of high-performance stainless steel products, including control pipelines, continuous oil pipes, test cables, heating cables, optical fiber temperature measurement cables, and multi-functional co-core continuous pipes. Established with a strong commitment to technological innovation and product quality, the company has become a trusted name in industries such as petroleum, coal, chemical, shipbuilding, and environmental protection.

Among its diverse range of offerings, the stainless steel ferrule joints produced by Jiangsu Laihua stand out for their exceptional quality and sealing performance. These components play a crucial role in ensuring the safe, reliable, and efficient operation of piping systems, especially in demanding environments like oil fields and petrochemical plants. This article explores the superior quality and sealing capabilities of the stainless steel ferrule joints manufactured by Jiangsu Laihua, and why they are an essential part of modern industrial applications.

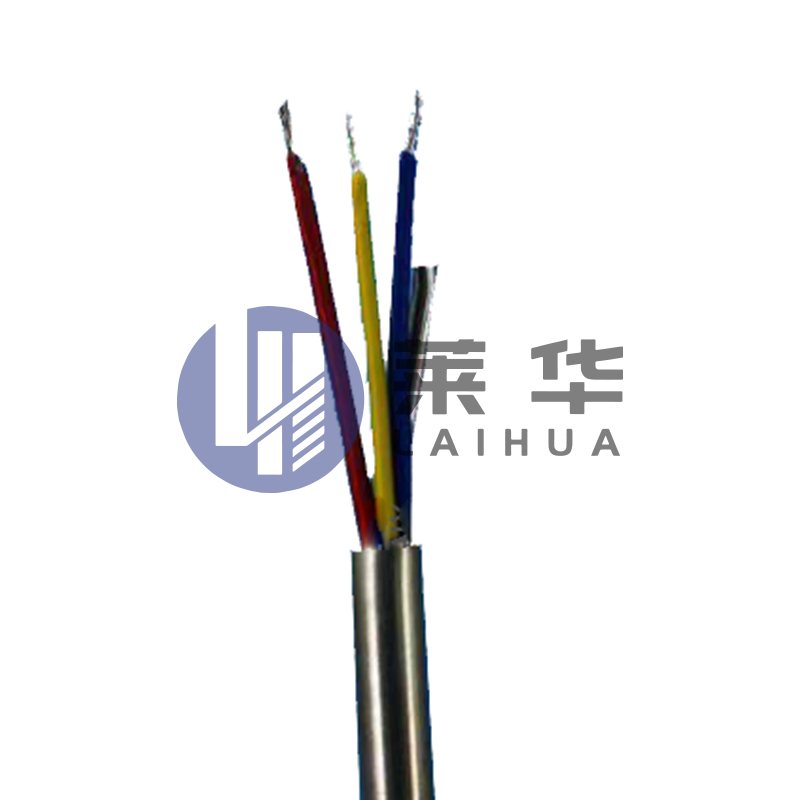

Ferrule joints are vital components used in the connection of stainless steel pipes, particularly in applications where high pressure, temperature, and corrosion resistance are critical. These joints consist of a metal ferrule, typically made of stainless steel, that is used to seal and secure the ends of pipes to prevent leaks. The sealing performance of these joints is of utmost importance, as even a small leak can lead to significant operational inefficiencies, environmental hazards, or safety risks.

Jiangsu Laihua’s stainless steel ferrule joints are specifically engineered to meet the stringent demands of high-pressure and high-temperature environments, especially in the oil and gas sector. Designed for use in both onshore and offshore oil fields, these ferrule joints ensure the integrity of critical fluid and gas transportation systems by providing a secure and durable seal.

The quality of stainless steel ferrule joints is a critical factor in their ability to perform reliably over long periods. Jiangsu Laihua Petroleum Equipment Co., Ltd. has invested heavily in advanced manufacturing techniques and quality control systems to ensure that each ferrule joint meets the highest industry standards.

Jiangsu Laihua uses high-quality stainless steel alloys to manufacture their ferrule joints, ensuring resistance to corrosion, high temperatures, and mechanical wear. The company sources materials that meet or exceed the requirements of international standards such as ASTM A312, ensuring that the ferrules can withstand the extreme conditions encountered in industries like petroleum, coal mining, and chemical processing. The stainless steel material used provides excellent resistance to corrosion from various chemicals, oils, and other harsh substances commonly found in these industries.

The manufacturing process at Jiangsu Laihua incorporates advanced technologies such as CNC machining, automated welding, and precision tooling to ensure that each ferrule joint is precisely crafted. The joints are fabricated to meet tight dimensional tolerances and ensure a perfect fit with the associated piping components. The high level of precision in the manufacturing process contributes significantly to the overall reliability and performance of the ferrule joints.

To ensure consistent quality, Jiangsu Laihua employs a robust quality management system that includes rigorous testing and inspection of each ferrule joint. The company’s quality inspection center is equipped with state-of-the-art testing equipment, including tensile test benches, Vickers hardness testers, and hydraulic testing machines. These tools allow for the thorough evaluation of each joint’s physical and mechanical properties, ensuring they meet or exceed the required performance specifications.

Each batch of ferrule joints undergoes a series of tests, including pressure testing, dimensional inspections, and corrosion resistance tests, to confirm that the joints meet the strict performance requirements for high-pressure and high-temperature applications. By adhering to these comprehensive quality control processes, Jiangsu Laihua guarantees that every ferrule joint is built to last and perform reliably under even the most challenging conditions.

The sealing performance of a ferrule joint is critical in preventing leakage and ensuring the safety and efficiency of piping systems. The stainless steel ferrule joints from Jiangsu Laihua are engineered to provide superior sealing performance, even under high pressure and extreme temperatures.

The ferrule joint design incorporates a precision-engineered ferrule that tightly compresses around the pipe during installation, creating a secure, leak-proof seal. The stainless steel ferrule is designed to expand slightly as it is tightened, forming a tight grip on the pipe and creating a durable seal that prevents fluid or gas leakage.

The excellent sealing performance is achieved by the high precision of the joint's machining, which ensures that the ferrule aligns perfectly with the pipe’s surface. This perfect fit is critical for preventing leaks, which could otherwise result in significant safety concerns, environmental hazards, or operational inefficiencies.

Jiangsu Laihua’s ferrule joints are specifically designed to handle high-pressure applications, which are common in the oil and gas industry. The joints can withstand pressures up to 300MPA, depending on the specifications, ensuring they provide a secure seal even under extreme operational conditions. In addition, the joints are built to perform reliably at high temperatures, making them ideal for use in oil wells, refineries, and other high-temperature environments.

The sealing components of these joints are also resistant to thermal expansion and contraction, ensuring that the seal remains intact despite fluctuations in temperature. This is particularly important in environments where temperature changes can cause materials to expand and contract, potentially compromising the integrity of the seal.

The stainless steel material used in the ferrule joints also provides excellent resistance to corrosion, ensuring that the joints maintain their sealing capabilities even in the presence of aggressive chemicals, moisture, and other corrosive substances. This corrosion resistance is especially important in industries like petroleum, where the pipes often carry harsh chemicals, oils, and gases that can degrade inferior materials over time.

The stainless steel ferrule joints manufactured by Jiangsu Laihua are widely used in a variety of industries, including petroleum, coal, chemical processing, and shipbuilding. These industries require highly reliable, durable, and efficient sealing solutions for their pipeline systems. The ferrule joints are employed in critical applications such as oil well pipelines, chemical reactors, and gas transport systems, where their superior sealing performance ensures safe and efficient operations.

Jiangsu Laihua’s ferrule joints have been successfully deployed in major oil fields, including Liaohe Oilfield, Daqing Oilfield, and Xinjiang Coal Mine, as well as in international markets such as Iran, the United States, and Russia. The company’s products have been widely praised for their exceptional quality and reliability, and the stainless steel ferrule joints are trusted by leading operators in the oil and gas sector.

The stainless steel ferrule joints from Jiangsu Laihua Petroleum Equipment Co., Ltd. exemplify the company’s commitment to quality, precision, and innovation. These high-performance joints provide superior sealing capabilities, ensuring the integrity of pipeline systems in high-pressure and high-temperature environments. With a focus on advanced manufacturing techniques, stringent quality control, and the use of premium materials, Jiangsu Laihua has established itself as a leader in providing reliable sealing solutions for industries such as petroleum, coal, and chemical processing.

英语

英语 西班牙语

西班牙语 阿拉伯语

阿拉伯语