Long-term maintenance and repair requirements for Square Stainless Steel Cables Wrapped Plastic Pipes from Jiangsu Laihua Petroleum Equipment Co., Ltd.

Jiangsu Laihua Petroleum Equipment Co., Ltd., a prominent manufacturer based in Hai'an City, Jiangsu Province, has earned a reputation for producing high-quality stainless steel products for demanding industries. Specializing in stainless steel high-pressure pipelines, continuous oil pipes, ultra-long high-temperature test cables, and optical fiber temperature measurement cables, the company has solidified its position as a leader in the production of durable, reliable, and cutting-edge piping solutions. Among its innovative products, the Square Stainless Steel Cables Wrapped Plastic Pipes stand out for their robustness, versatility, and suitability for long-term, heavy-duty applications. In this article, we will explore the long-term maintenance and repair requirements for these pipes, essential for ensuring their durability and optimal performance.

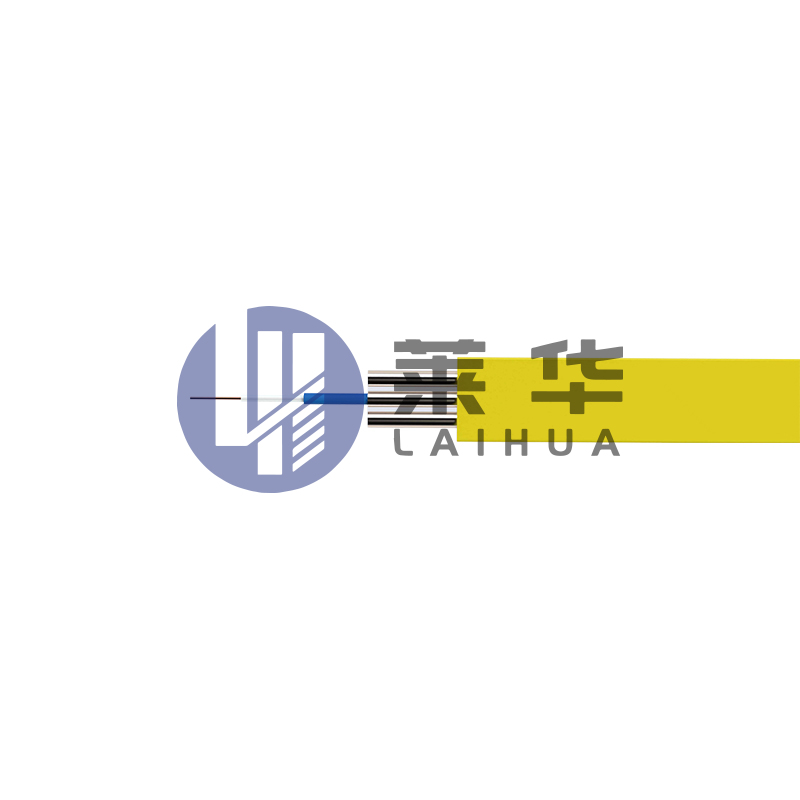

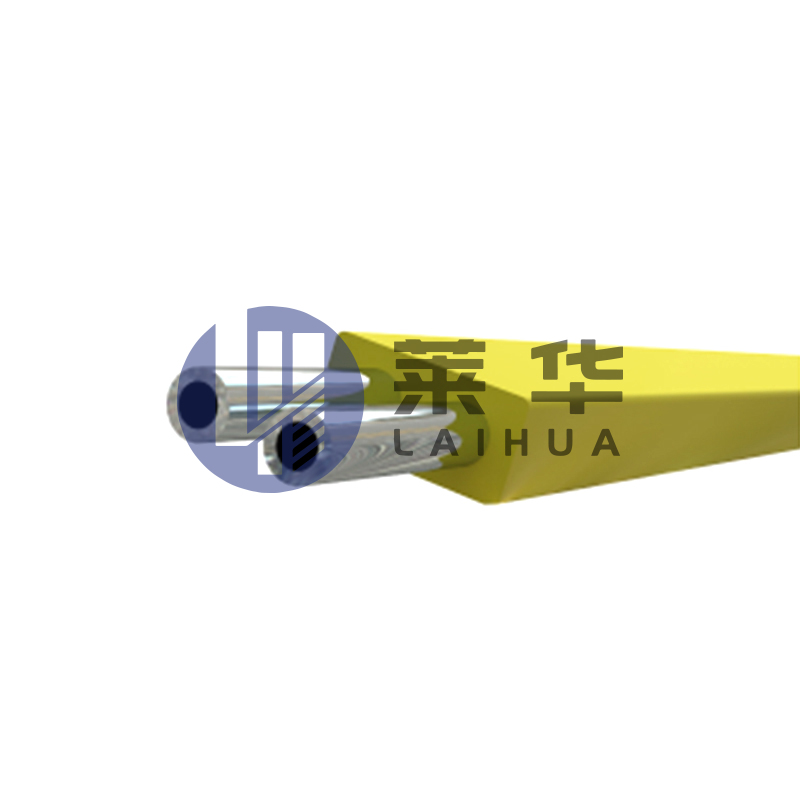

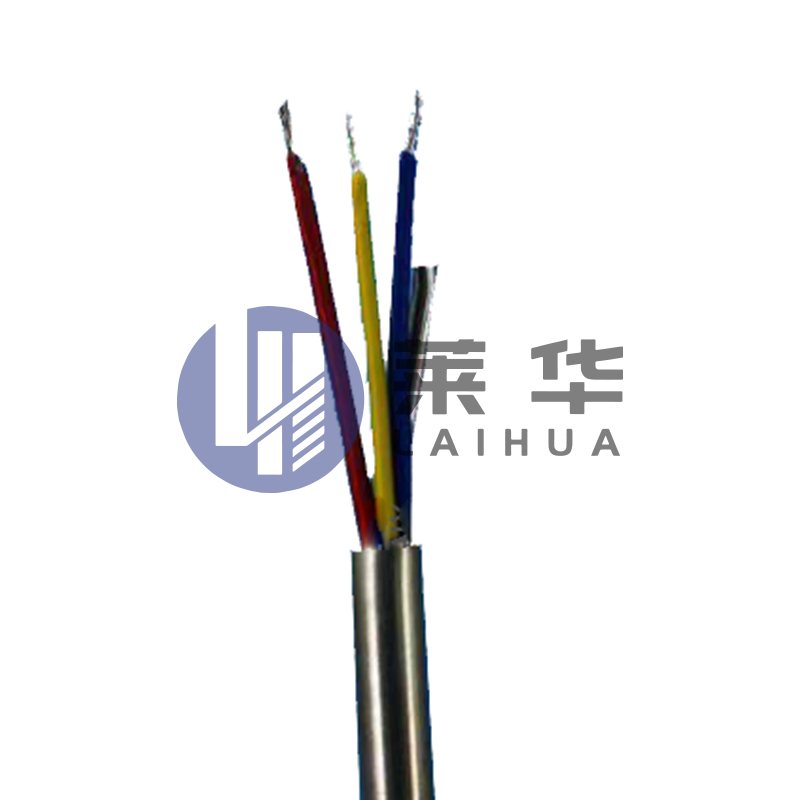

The Square Stainless Steel Cables Wrapped Plastic Pipes produced by Jiangsu Laihua are engineered for use in harsh industrial environments, particularly where fluid transportation and high-pressure control are needed. These pipes feature a core of stainless steel that is wrapped with a protective plastic layer, offering superior corrosion resistance and mechanical strength. The design is particularly well-suited for industries such as petroleum, coal, chemical, and shipbuilding, where the equipment must endure extreme pressures, temperatures, and corrosive elements.

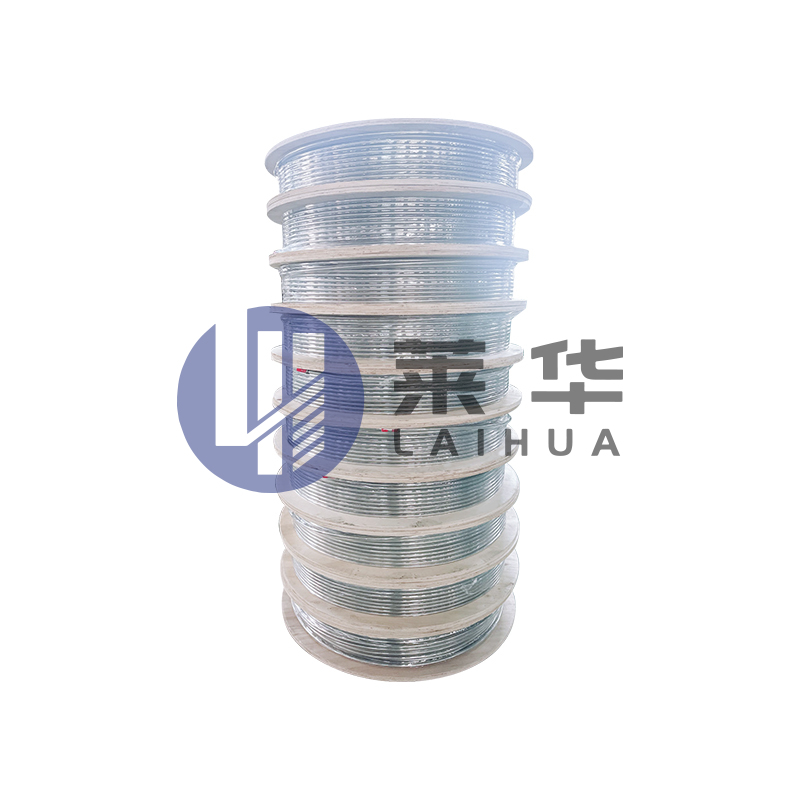

These pipes are also used in applications that require long lengths and high mechanical stability, such as underground coal gasification projects and high-pressure fluid transport systems. With more than 5,000 tons of annual production capacity, Jiangsu Laihua ensures that these products are manufactured to the highest standards of performance and reliability, meeting both domestic and international quality requirements.

The Square Stainless Steel Cables Wrapped Plastic Pipes offer numerous advantages that make them an essential part of industrial infrastructure:

The stainless steel core provides excellent resistance to rust, corrosion, and scaling, making these pipes highly durable in harsh environments.

The combination of stainless steel and plastic wrapping ensures superior strength, allowing the pipes to withstand high pressures without failure.

These pipes maintain structural integrity even at elevated temperatures, ensuring continuous operation in extreme conditions.

The flexible plastic wrapping provides an additional layer of protection, safeguarding the stainless steel core from physical damage and external corrosion.

While the pipes are designed to be durable, long-term maintenance and repair are essential to preserving their functionality and extending their lifespan.

Routine maintenance is crucial to ensure the longevity of Square Stainless Steel Cables Wrapped Plastic Pipes, particularly in demanding industrial applications. Below are key maintenance requirements:

Periodic inspections are essential to check for any signs of wear, corrosion, or physical damage to the pipes. Both the stainless steel core and the plastic wrapping should be examined for any cracks, dents, or chemical degradation. Inspections should focus on areas where stress or bending is most likely to occur, such as at joints or connection points.

Over time, internal deposits or scaling can form inside the pipes due to the buildup of minerals, chemicals, or other contaminants. These deposits can restrict the flow of fluids, reducing the efficiency of the system. Regular cleaning with appropriate chemicals and tools is necessary to remove these buildups and ensure the pipes' continued performance.

To verify the structural integrity of the pipes, periodic pressure testing is essential. This helps to detect any potential leaks or weaknesses in the system. Pressure testing should be conducted at intervals recommended by the manufacturer to prevent any unforeseen pipe failure during operations.

Since these pipes are exposed to varying temperature conditions, regular temperature checks are important to ensure that the pipes are not exposed to temperatures outside their design limits. If the pipes are exposed to extreme heat or cold, they may experience deformation or mechanical failure.

Even with regular maintenance, some wear and tear are inevitable over time. The most common repair needs for Square Stainless Steel Cables Wrapped Plastic Pipes include:

Small cracks or holes in the stainless steel core can compromise the integrity of the pipe. Such damage should be addressed immediately through welding or other repair methods that restore the pipe’s strength. If the plastic wrapping is damaged, it may need to be replaced or reinforced.

Plastic Wrapping Replacement: The plastic wrapping may experience wear or degradation, especially in environments with extreme chemical exposure. If the wrapping is damaged, it should be replaced or patched to maintain the pipe's protective layer. Temporary repairs can be made using high-quality plastic adhesives or wraps until the pipe is properly serviced.

Over time, the seals around pipe joints may degrade, causing leaks. In this case, the joints should be cleaned and resealed using high-strength sealants or gaskets that are compatible with the pipe’s material and the fluids being transported.

For repairs to be effective, it is essential to use the appropriate materials that match the specifications of the original pipes. Jiangsu Laihua provides comprehensive support for the repair and maintenance of its products, ensuring that customers have access to high-quality materials and expert advice.

To ensure the long-term functionality of Square Stainless Steel Cables Wrapped Plastic Pipes, users should consider the following:

The pipes' performance can be affected by environmental conditions such as humidity, exposure to harsh chemicals, or extreme temperature fluctuations. Regular monitoring of the operating environment is essential to prevent damage caused by these factors.

Ensuring that the pipes are correctly installed and handled is key to preventing premature wear. Proper alignment during installation can prevent undue stress on the pipes and reduce the risk of cracks or deformations.

When repairs or replacements are necessary, it is important to use genuine parts and materials provided by Jiangsu Laihua. This ensures that the replacement components meet the same high standards of performance and compatibility as the original parts.

The Square Stainless Steel Cables Wrapped Plastic Pipes from Jiangsu Laihua Petroleum Equipment Co., Ltd. are designed to provide excellent performance in demanding industrial applications. However, to maintain their reliability, it is essential to follow routine maintenance and repair protocols. Regular inspections, pressure testing, and cleaning are vital for the long-term health of these pipes. Additionally, prompt repairs to any damage—such as cracks or worn-out plastic wrappings—are necessary to avoid failure and ensure the continued efficiency of the system. By adhering to these maintenance and repair guidelines, companies can extend the life of their Square Stainless Steel Cables Wrapped Plastic Pipes and keep their operations running smoothly for years to come. With Jiangsu Laihua's commitment to quality and customer satisfaction, users can rest assured that they have access to the necessary tools and expertise for optimal pipe maintenance and repair.

英语

英语 西班牙语

西班牙语 阿拉伯语

阿拉伯语