Jiangsu Laihua Petroleum Equipment Co., Ltd.'s Coiled tubing tow winch is adaptable to high temperature, high pressure, high corrosion and other environments

Jiangsu Laihua Petroleum Equipment Co., Ltd., located in Hai'an City, Jiangsu Province, is a leading manufacturer specializing in the production of high-quality stainless steel products, including high-pressure coiled tubing, oil pipes, cables, and winch supporting equipment. With a strong presence in various industries such as petroleum, coal, chemical processing, and shipbuilding, the company is committed to providing advanced, durable, and reliable solutions for challenging operating environments. One of the standout products in the company’s extensive portfolio is the coiled tubing tow winch, a piece of equipment specifically designed to perform under the extreme conditions typically encountered in the oil, gas, and coal industries. This article explores the versatility and adaptability of Jiangsu Laihua’s coiled tubing tow winch, particularly in high temperature, high pressure, and high corrosion environments.

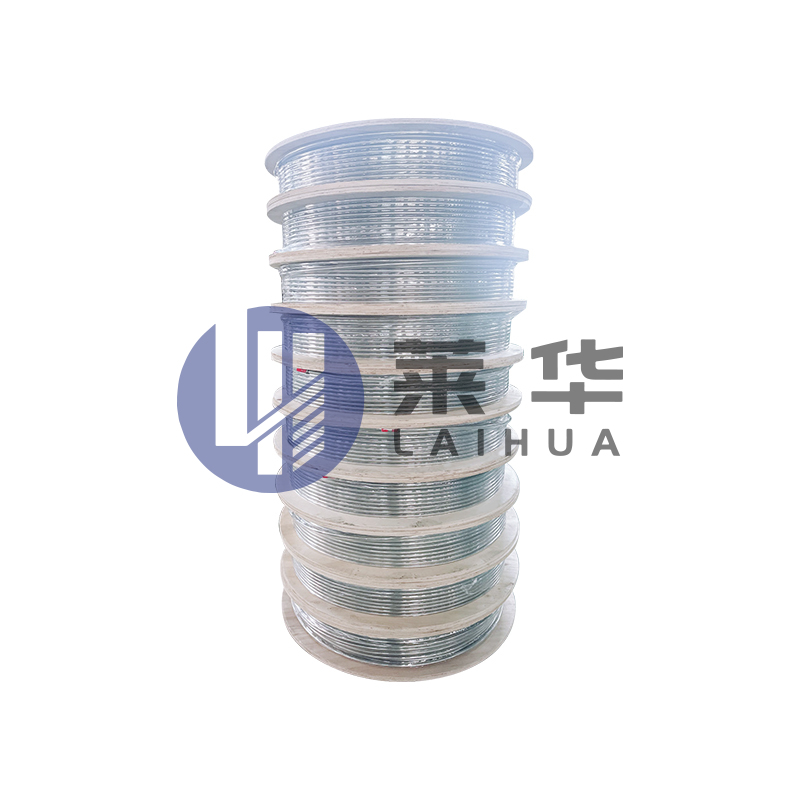

Coiled tubing tow winches are critical pieces of equipment used in the oil and gas industry for deploying and retrieving coiled tubing, which is widely used for drilling, well intervention, and other applications. The winch system helps operators manage the coiled tubing efficiently, even in the most challenging conditions. The design of the coiled tubing tow winch is essential to ensuring safe, reliable, and efficient operation, especially in environments that demand resistance to high pressure, high temperature, and corrosive substances.

Jiangsu Laihua’s coiled tubing tow winch is engineered to meet these exacting standards, offering superior adaptability and performance for use in harsh environments. Designed for heavy-duty use, this winch system is equipped with advanced features that enable it to handle the demands of modern-day drilling and intervention operations in the oil and gas, coal, and petrochemical industries.

High-temperature conditions are a common challenge in industries such as oil and gas exploration, particularly when dealing with deep well drilling and heavy oil extraction. In these extreme environments, the temperature can reach levels that can compromise the structural integrity of standard equipment. Jiangsu Laihua's coiled tubing tow winch is specifically designed to operate efficiently in high-temperature environments, ensuring reliability under heat stress.

The components of the winch are manufactured from high-quality, heat-resistant alloys that can withstand the intense heat found in oil wells, refineries, and other high-temperature settings. These materials ensure the winch maintains its structural integrity and functionality, even in conditions where temperatures exceed normal operating limits.

Jiangsu Laihua has incorporated advanced thermal management features into its coiled tubing tow winch, including heat dissipation systems and protective coatings, to prevent overheating during operation. These systems ensure that the winch remains operational for extended periods without degradation, even when exposed to high temperatures.

The ability of equipment to perform reliably under high pressure is essential in industries such as oil and gas drilling, where high-pressure fluids and gases are often encountered. The coiled tubing tow winch from Jiangsu Laihua is engineered to perform seamlessly in high-pressure environments, ensuring safe and efficient deployment and retrieval of coiled tubing.

The winch is designed to operate safely under high-pressure conditions, which are typical in deep drilling operations and well interventions. The winch’s pressure-resistant design incorporates robust seals, reinforced components, and advanced hydraulics to prevent failure or leakage under extreme pressure.

Given the high-risk nature of high-pressure environments, the coiled tubing tow winch includes several safety features that prevent accidents and ensure safe operation. These features include pressure relief systems, emergency stop functions, and fail-safe mechanisms that automatically engage in the event of an equipment malfunction. This ensures that the winch can maintain its functionality and prevent damage to the tubing or surrounding infrastructure under pressure.

Corrosion is a significant concern for equipment used in industries that operate in chemically aggressive environments, such as oil and gas exploration. The corrosive nature of fluids, chemicals, and gases found in these industries can rapidly degrade equipment, leading to costly repairs and downtime. Jiangsu Laihua’s coiled tubing tow winch is specifically designed to resist corrosion, ensuring long-term durability and performance.

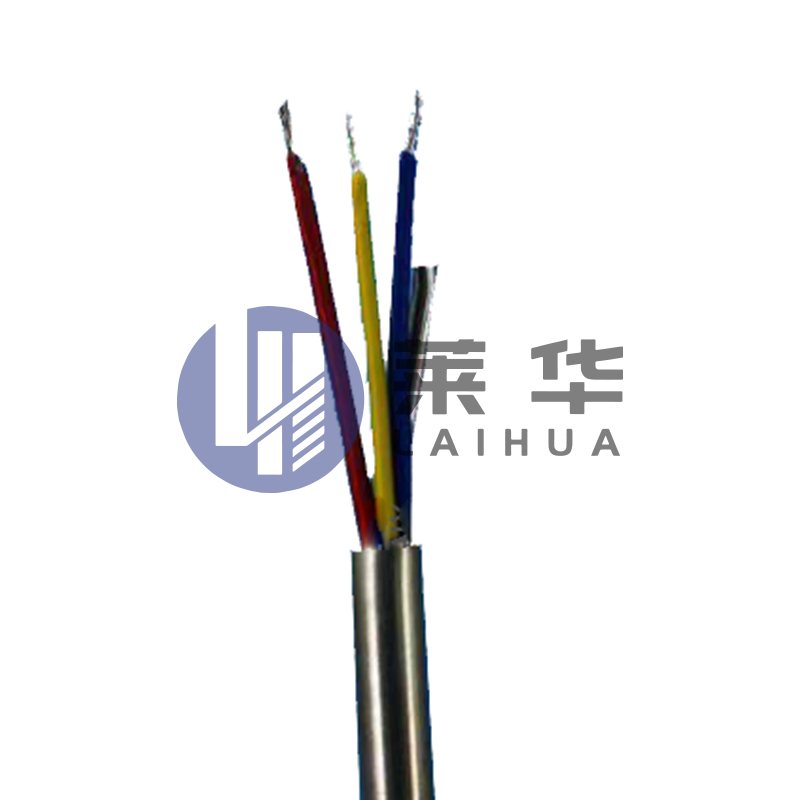

The winch’s components are made from stainless steel and other corrosion-resistant alloys, which are chosen for their ability to withstand exposure to harsh chemicals, saltwater, and other corrosive substances. This ensures that the winch remains fully functional even in the most challenging environmental conditions, such as offshore oil rigs, where equipment is often exposed to salty, humid air and harsh marine environments.

In addition to using corrosion-resistant materials, the winch is coated with protective layers that further enhance its ability to resist corrosion. These coatings provide an additional layer of protection, ensuring that the winch remains operational for years without suffering from the negative effects of corrosion.

The coiled tubing tow winch from Jiangsu Laihua is not only designed for the oil and gas industry but also for use in other sectors that require reliable and durable equipment for handling heavy-duty pipes and cables. These include industries such as coal mining, petrochemical processing, and shipbuilding, where similar environmental challenges are present.

In the oil and gas industry, the coiled tubing tow winch is commonly used for deploying and retrieving coiled tubing for well interventions, drilling, and completion operations. The winch is capable of handling high tensile loads, ensuring smooth operation even in deep wells where coiled tubing can be subjected to significant pressure and high temperatures.

In the coal mining industry, coiled tubing tow winches are used for managing coiled tubing during underground gasification or exploration projects. Similarly, the petrochemical industry benefits from the winch's ability to deploy and retrieve pipes and cables in chemical plants, where equipment is exposed to both high pressure and corrosive chemicals.

Jiangsu Laihua Petroleum Equipment Co., Ltd.'s coiled tubing tow winch stands out as a highly adaptable and reliable solution for challenging environments in industries like oil and gas, coal mining, and petrochemical processing. Engineered to operate in high temperature, high pressure, and high corrosion environments, the winch offers superior performance and durability. Thanks to its heat-resistant materials, pressure-resistant design, and corrosion protection, the coiled tubing tow winch from Jiangsu Laihua provides a robust solution for modern-day industrial challenges, ensuring safe and efficient operations in even the most demanding conditions. As the company continues to advance its technology and expand its market reach, the coiled tubing tow winch remains a testament to Jiangsu Laihua’s commitment to delivering high-quality, innovative solutions for industries worldwide.

英语

英语 西班牙语

西班牙语 阿拉伯语

阿拉伯语