The corrosion resistance and waterproof performance of the stainless steel fiber optic testing cable from Jiangsu Laihua Petroleum Equipment Co., Ltd.

Jiangsu Laihua Petroleum Equipment Co., Ltd., located in Hai'an City, Jiangsu Province, is a leading manufacturer known for its advanced technological expertise in producing high-quality stainless steel products, including high-pressure control pipelines, continuous oil pipes, and specialty cables. Among their standout products is the stainless steel fiber optic testing cable, which has garnered significant recognition for its outstanding corrosion resistance and waterproof performance. These cables are particularly suited for use in industries such as petroleum exploration, coal mining, chemical processing, and environmental monitoring, where durability and reliability in harsh environments are paramount.

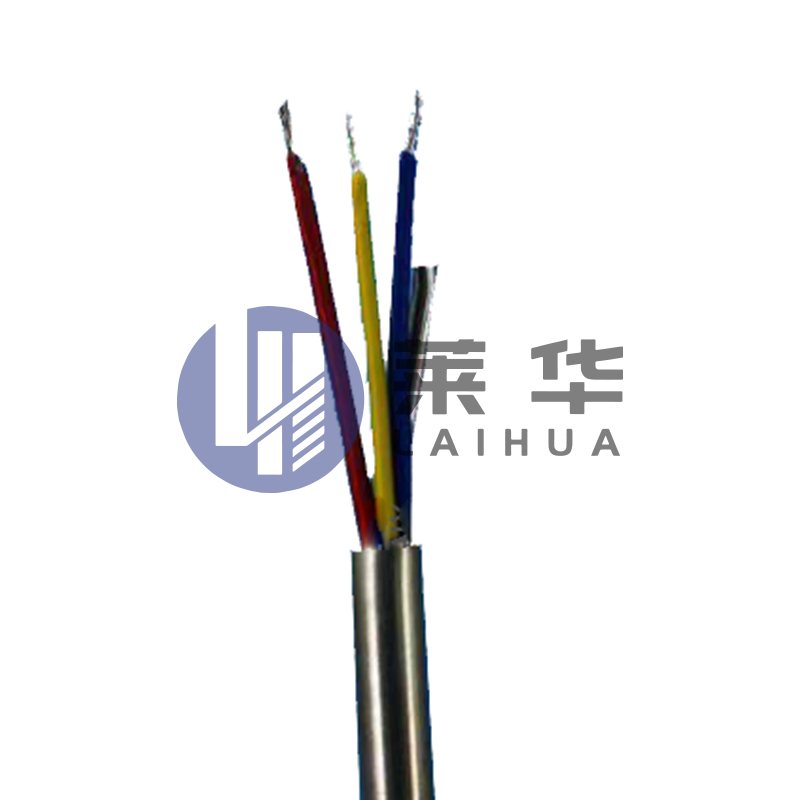

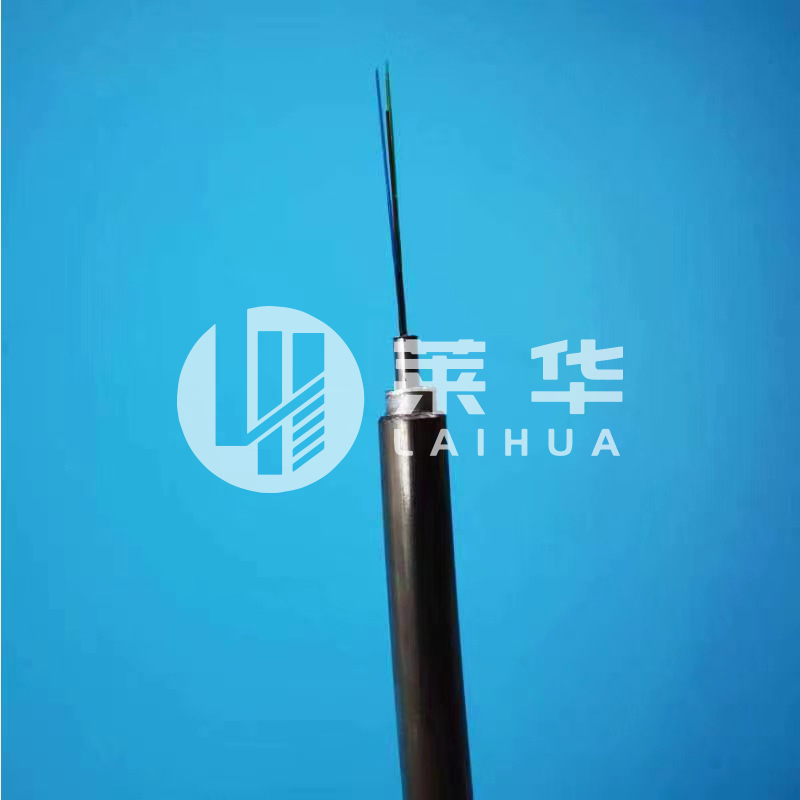

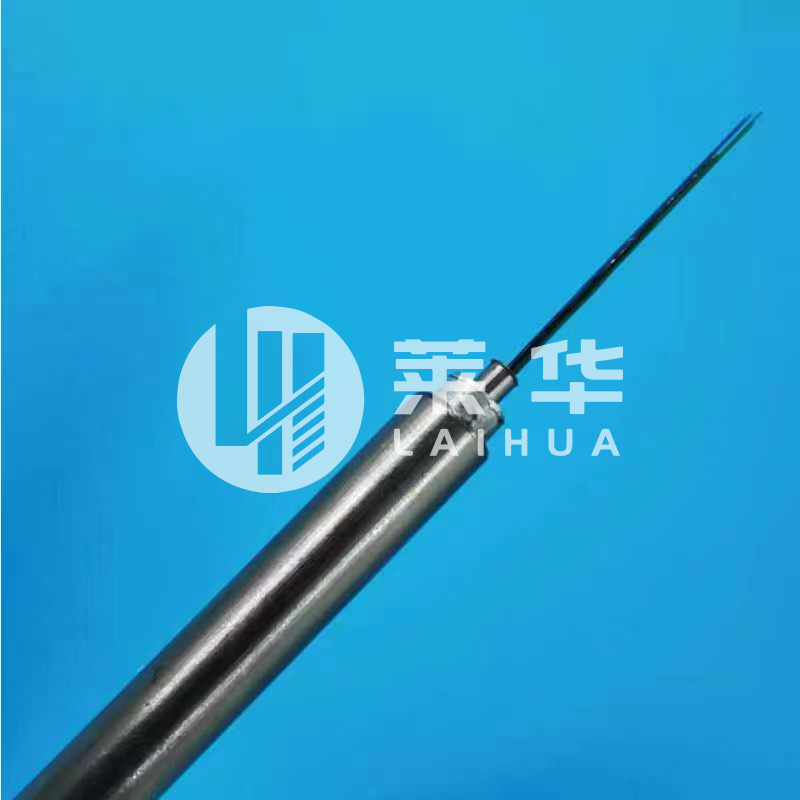

Stainless steel fiber optic testing cables from Jiangsu Laihua are designed for high-temperature, high-pressure environments, making them essential for applications such as oil well monitoring, heavy oil heating systems, and temperature measurement. These cables combine the mechanical strength of stainless steel with the advanced capabilities of fiber optics to deliver reliable performance in critical applications. The ability to withstand extreme conditions, particularly corrosion and water exposure, is a key feature that sets Laihua’s cables apart in the market.

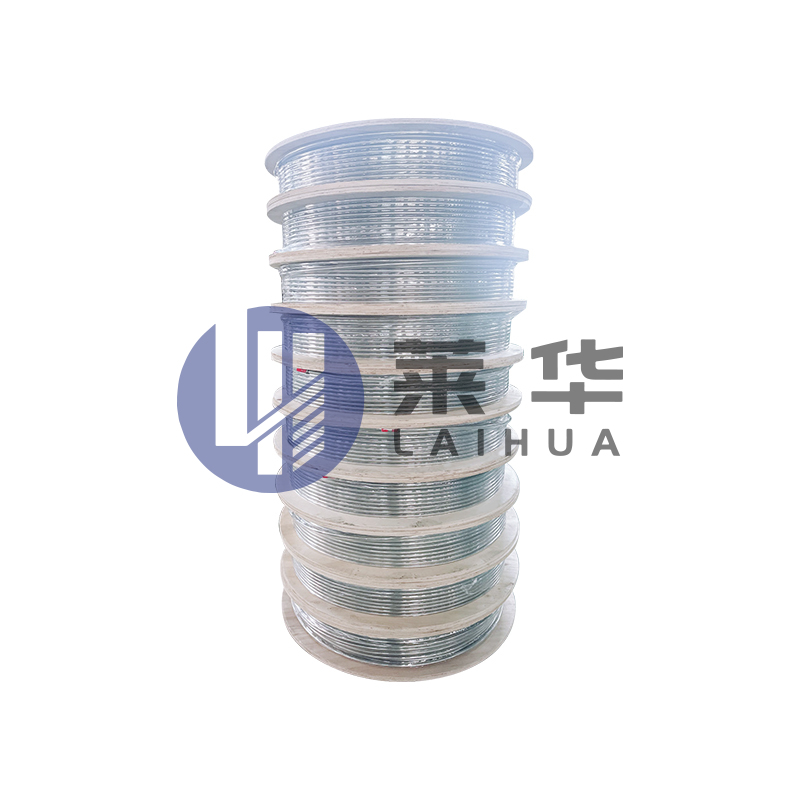

The company’s commitment to quality is reflected in its extensive research and development efforts, which have resulted in the creation of cables that not only meet but exceed industry standards. The cables are manufactured with a focus on both functionality and longevity, ensuring that they can operate in challenging environments without compromising performance.

One of the key attributes of the stainless steel fiber optic testing cables produced by Jiangsu Laihua is their exceptional corrosion resistance. Corrosion is a major concern in industries such as petroleum and coal mining, where cables are frequently exposed to harsh chemicals, saltwater, and high humidity environments. In these conditions, corrosion can lead to the degradation of materials, resulting in failures that could have costly and potentially dangerous consequences.

The stainless steel used in Laihua’s fiber optic testing cables is carefully selected for its ability to resist corrosion. The company utilizes high-grade stainless steel alloys that are specifically designed to endure exposure to corrosive substances, including acids, salts, and other industrial chemicals. This ensures that the cables maintain their structural integrity and performance over extended periods, even in environments where corrosion is a constant threat.

Additionally, the use of stainless steel as the outer armor of the cable provides an added layer of protection against corrosion. Stainless steel’s inherent resistance to rust and degradation makes it an ideal material for cables used in the oil and gas industry, as well as other sectors that require high performance in corrosive environments.

The corrosion resistance of these cables has been extensively tested under various conditions, including exposure to seawater, acidic solutions, and high humidity. These rigorous tests confirm that Laihua’s cables outperform many of their competitors, making them a reliable choice for applications in harsh and corrosive environments.

Waterproof performance is another critical factor in ensuring the reliability and longevity of fiber optic testing cables, especially when they are used in underwater or subaqueous environments such as oil wells, pipelines, and marine installations. Jiangsu Laihua’s stainless steel fiber optic testing cables are designed with advanced waterproofing technology to prevent water ingress that could compromise their functionality.

The waterproof performance of these cables is achieved through a combination of material selection and design features. The stainless steel armoring serves as a primary barrier against water penetration, providing a strong and protective outer layer. In addition, the cable’s internal components, including the fiber optic fibers, are encapsulated in a waterproof sheath that prevents water from reaching the sensitive components of the cable.

Laihua’s cables have been subjected to various waterproof tests, including immersion in water for extended periods and exposure to high-pressure water environments. The cables’ ability to maintain their functionality under these conditions ensures that they are ideal for use in offshore oil rigs, underwater pipelines, and other applications where water exposure is a constant concern.

The waterproof capabilities of the stainless steel fiber optic testing cables make them highly suitable for use in oil and gas exploration, where cables are often deployed in subsea environments or deep well conditions. In these scenarios, the ability to withstand prolonged exposure to water without degradation is essential for ensuring the cables' long-term performance.

The superior corrosion resistance and waterproof performance of Jiangsu Laihua’s stainless steel fiber optic testing cables are the result of advanced manufacturing techniques and stringent quality control processes. The company utilizes cutting-edge production facilities, including stainless steel pipe production lines, vacuum bright furnaces, and stretching units, to manufacture these high-performance cables.

Laihua’s quality inspection center plays a critical role in ensuring that each cable meets the required specifications and performs reliably under extreme conditions. The center is equipped with advanced testing equipment, such as tensile test benches, hydraulic testing machines, spectrometers, and eddy current flaw detectors, which are used to evaluate the mechanical, chemical, and physical properties of the cables.

Before being delivered to customers, each stainless steel fiber optic testing cable undergoes a series of tests to verify its corrosion resistance, waterproof performance, tensile strength, and other critical properties. This rigorous testing ensures that only the highest-quality cables are shipped, providing customers with a product they can rely on in even the most demanding applications.

Jiangsu Laihua’s stainless steel fiber optic testing cables are widely used in a variety of industries that require reliable, durable, and high-performance cables. Some of the key applications include:

Petroleum Industry: For monitoring oil wells, temperature measurement, and other critical operations in oil exploration and extraction.

Coal Mining: In underground mining operations, where cables are exposed to harsh environments and need to withstand both corrosion and water exposure.

Chemical and Shipbuilding Industries: For temperature measurement and control systems in corrosive and wet environments.

Environmental Monitoring: For long-term deployment in coastal or underwater installations where cables must endure exposure to seawater and chemicals.

The cables’ corrosion resistance and waterproof performance make them ideal for these applications, where failure can result in significant financial losses and safety risks.

Jiangsu Laihua Petroleum Equipment Co., Ltd. has established itself as a leader in producing high-performance stainless steel fiber optic testing cables that excel in corrosion resistance and waterproof performance. These cables are designed to meet the rigorous demands of industries such as petroleum, coal mining, and environmental protection, offering long-lasting reliability in extreme conditions. With their advanced manufacturing techniques, high-quality materials, and rigorous testing procedures, Laihua’s cables are well-suited to provide exceptional performance in even the harshest environments.

英语

英语 西班牙语

西班牙语 阿拉伯语

阿拉伯语