Mechanical properties of Jiangsu Laihua Petroleum Equipment Co., Ltd.'s stainless steel (armored) high-temperature testing cable in terms of tensile and compressive strength

Jiangsu Laihua Petroleum Equipment Co., Ltd., located in Hai'an City, Jiangsu Province, is renowned for its innovation and high-quality production of stainless steel products, including high-pressure control pipelines, oil pipes, and various specialty cables. Among these, the company’s stainless steel (armored) high-temperature testing cables stand out due to their critical role in industries that require high-performance materials. These cables are designed for use in demanding environments such as oil and gas exploration, coal mining, and other heavy-duty industrial sectors. This article delves into the mechanical properties of these high-temperature testing cables, focusing on their tensile and compressive strength, two essential factors for ensuring reliability and durability.

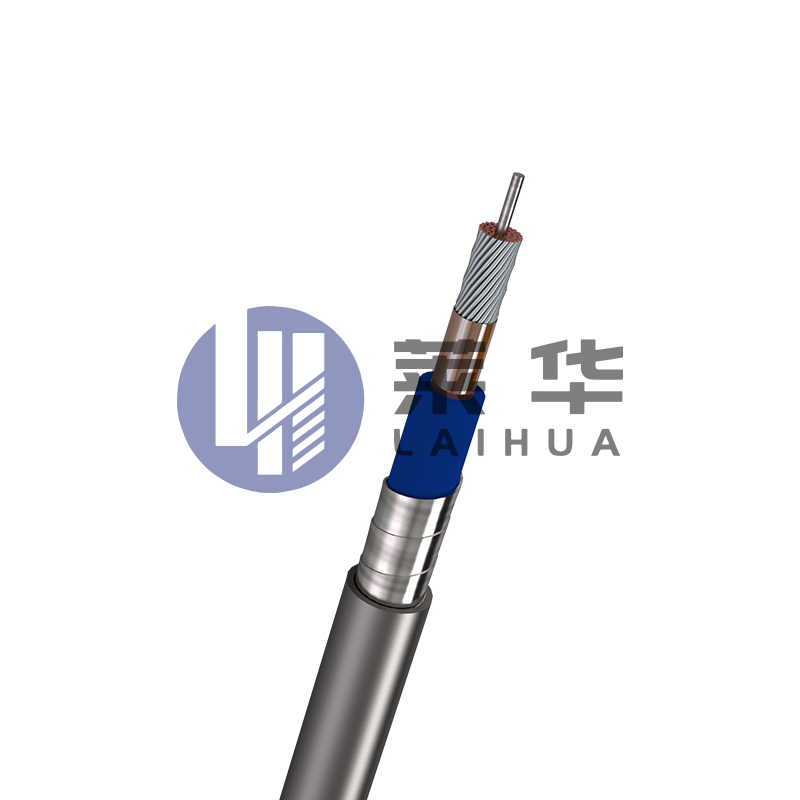

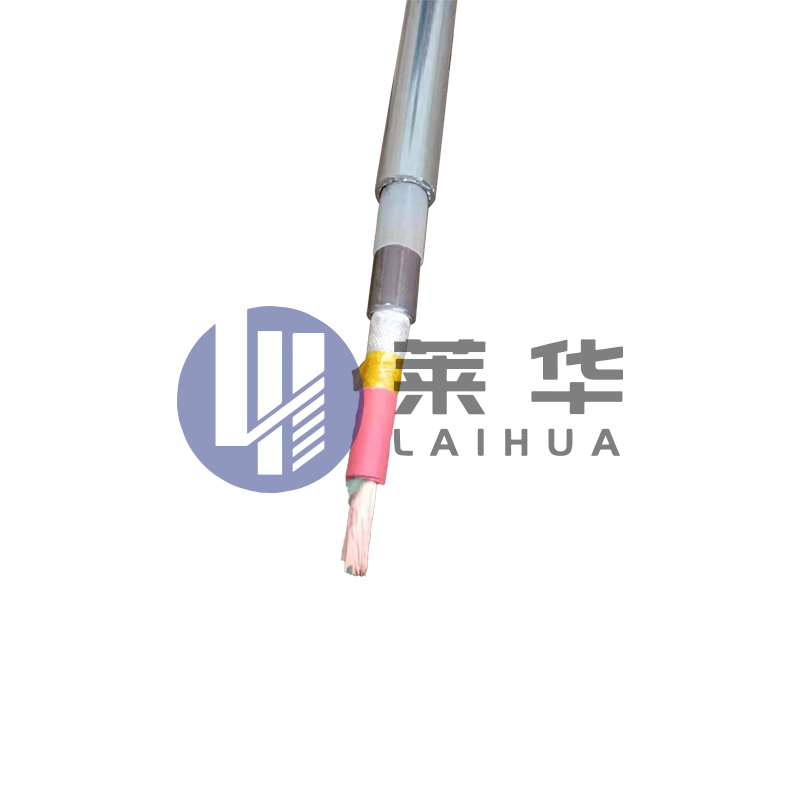

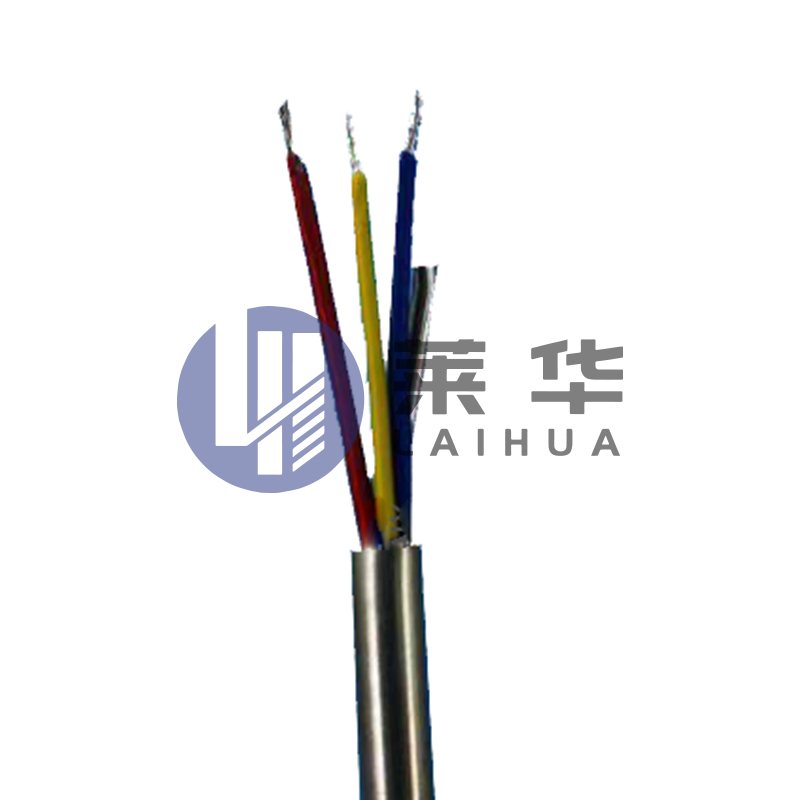

Jiangsu Laihua's stainless steel (armored) high-temperature testing cables are engineered to meet the rigorous demands of industries such as petroleum, coal, and chemical production, where high-pressure and high-temperature environments are prevalent. These cables are often used in oil well heavy oil heating systems, optical fiber temperature measurement applications, and other high-temperature scenarios. The incorporation of stainless steel armor enhances their durability and resistance to mechanical damage, making them indispensable in harsh operating conditions.

The mechanical properties of these cables, especially their tensile and compressive strengths, are fundamental to their ability to function reliably over extended periods. Tensile strength refers to the maximum stress a material can withstand while being stretched or pulled before breaking, while compressive strength measures the ability of a material to resist forces that would compress or shorten it. Both these properties ensure that the cables can withstand the stresses and strains imposed by high-pressure, high-temperature environments.

Tensile strength is a crucial mechanical property for high-temperature testing cables because it directly impacts the cable’s ability to endure stretching forces without failure. Jiangsu Laihua’s stainless steel (armored) high-temperature testing cables are designed with materials that exhibit superior tensile strength, ensuring that the cables can withstand the mechanical forces that occur during operation, installation, and routine maintenance.

The stainless steel used in Laihua’s cables is chosen for its high strength-to-weight ratio, allowing for flexibility without compromising durability. Additionally, the armored layer, which consists of high-strength stainless steel wires, enhances the tensile strength, offering added protection against mechanical stresses. The tensile strength of these cables is further optimized through advanced manufacturing processes, including the use of stretching units and high-precision welding techniques, which ensure that the cables retain their integrity under tension.

In practical applications, tensile strength is vital for cables used in deep wells, oil rigs, and other high-stress environments. These cables often face considerable forces, whether from installation, mechanical impact, or environmental factors such as temperature fluctuations and pressure changes. The ability to maintain structural integrity under such conditions makes the cables highly reliable and effective in demanding scenarios.

Compressive strength is another essential property of stainless steel (armored) high-temperature testing cables. These cables must be able to resist compressive forces that could cause deformation or failure, particularly when used in high-pressure environments, such as those found in oil wells or underground mining operations. The armored construction of these cables provides a critical layer of protection, allowing them to resist compressive forces without compromising their functional performance.

The stainless steel armoring acts as a safeguard, absorbing and distributing the compressive forces exerted on the cable. The cable’s core, which typically houses the conductors and other essential components, is designed to withstand compression without losing its ability to transmit signals or measure temperatures. The combination of stainless steel’s inherent resistance to corrosion and the cable’s robust construction ensures that the compressive strength remains high even in harsh conditions.

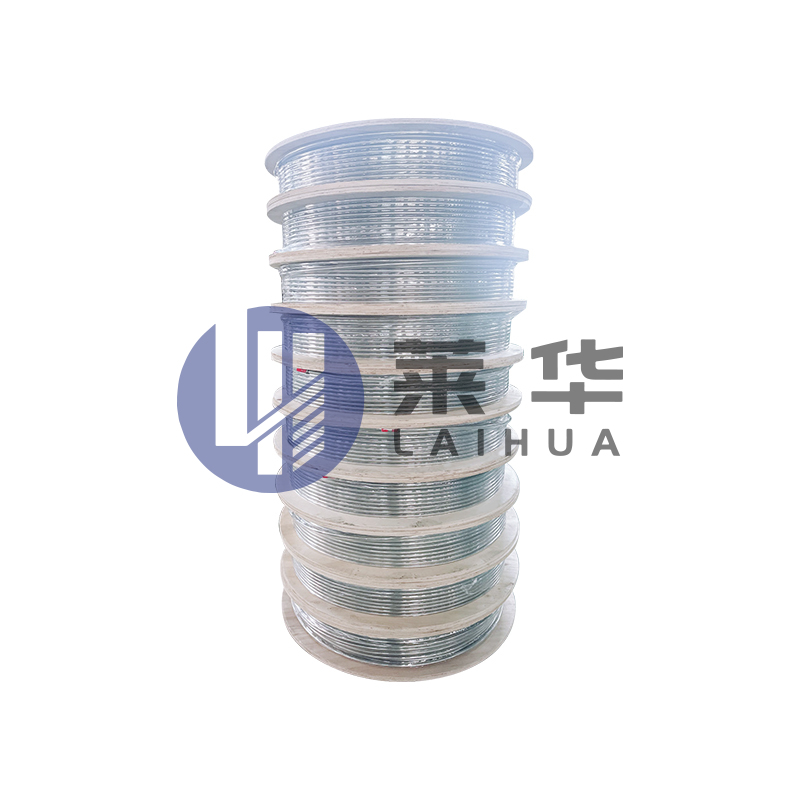

Moreover, Jiangsu Laihua’s high-temperature testing cables undergo stringent quality control processes, which include compressive strength testing in simulated environments. This ensures that the cables perform reliably under actual working conditions, where they are often exposed to significant external pressures.

Jiangsu Laihua’s stainless steel (armored) high-temperature testing cables are manufactured using advanced techniques that enhance both tensile and compressive strength. The use of high-quality stainless steel, combined with precise manufacturing processes, results in cables that exhibit outstanding mechanical properties.

The company’s production facilities include state-of-the-art equipment such as tensile test benches, hydraulic testing machines, and spectrometers to evaluate the mechanical properties of the cables. By subjecting the cables to rigorous testing, Laihua ensures that their tensile and compressive strength meet or exceed industry standards. Additionally, the company has established a robust quality assurance system, with a dedicated inspection center to perform detailed assessments of all products before they are shipped to clients.

The cables are also designed with flexibility in mind, allowing them to perform well under both tensile and compressive stress while maintaining their structural integrity. The stainless steel armoring, for instance, is precisely engineered to offer flexibility without compromising strength, making it well-suited for complex installations where bending and movement are required.

Jiangsu Laihua’s stainless steel (armored) high-temperature testing cables are widely used in industries that require cables to function under extreme conditions. The oil and gas industry, for example, often involves high-pressure, high-temperature environments that demand cables with superior tensile and compressive strength. These cables are used in applications such as oil well monitoring, temperature measurement, and control systems.

In coal mining, where cables are exposed to high pressures and harsh underground conditions, the compressive and tensile strength of these cables ensures they remain intact and functional. Additionally, the cables are resistant to the corrosive effects of chemicals and high temperatures, making them suitable for use in a wide range of industries, including shipbuilding, food processing, and environmental protection.

The mechanical properties of Jiangsu Laihua Petroleum Equipment Co., Ltd.'s stainless steel (armored) high-temperature testing cables, particularly their tensile and compressive strength, are essential to their performance and reliability in high-pressure, high-temperature environments. Through the use of advanced manufacturing techniques, high-quality materials, and stringent testing protocols, Laihua ensures that its cables meet the demands of industries such as petroleum, coal, chemical processing, and more. The company’s commitment to quality and innovation has established it as a trusted supplier of durable and high-performance cables, capable of withstanding the most challenging operational conditions.

英语

英语 西班牙语

西班牙语 阿拉伯语

阿拉伯语