Cat:Products

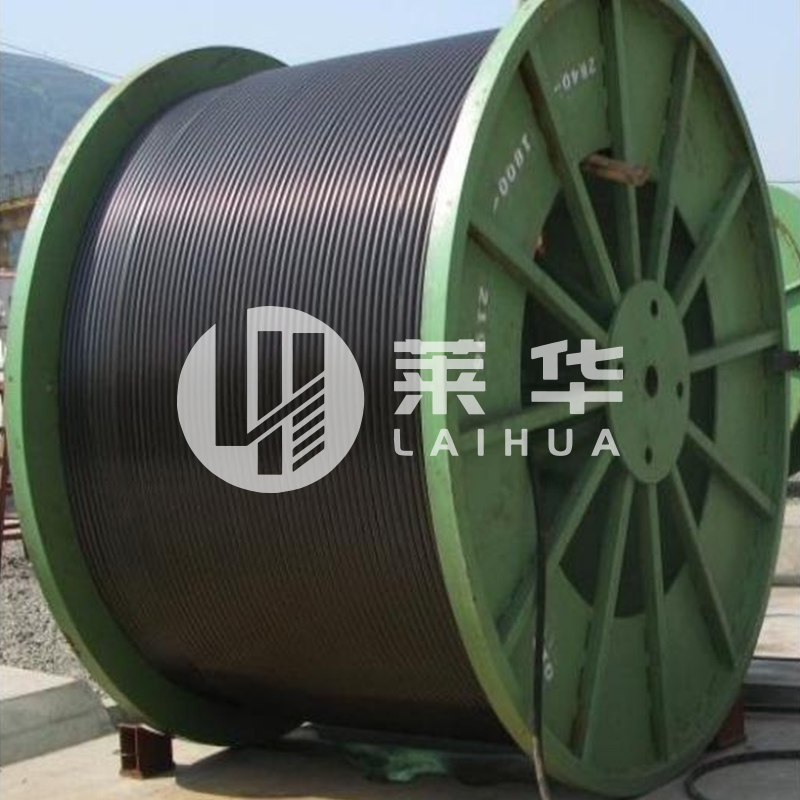

Continuous tubing, also known as flexible tubing or flexible tubing, is widely used in the fields of well workover, logging and drilling, etc. Its pro...

See Details

In the world of oil transportation, the materials we choose to use can make or break the performance of our systems. Stainless steel continuous oil pipes have become a popular choice due to their durability, resistance to corrosion, and overall reliability. However, these pipes are not immune to the effects of temperature and pressure. Understanding how these factors influence their performance is crucial for engineers and operators alike.

The Role of Temperature

Temperature plays a significant role in the performance of stainless steel continuous oil pipes. As temperatures rise, the metal expands, which can lead to changes in structural integrity. For instance, at high temperatures, the yield strength of stainless steel can decrease, making it more susceptible to deformation and failure under load. According to a study published in the Journal of Materials Science, stainless steel can lose up to 30% of its yield strength at elevated temperatures, especially above 600°C (1112°F).

Moreover, elevated temperatures can also accelerate corrosion processes, particularly in the presence of aggressive media such as sulfur compounds. This phenomenon is often referred to as "high-temperature corrosion," which can significantly reduce the lifespan of the pipes. Therefore, it is essential to monitor operating temperatures closely and implement temperature control measures to ensure optimal performance.

The Effect of Pressure

Pressure is another critical factor that impacts the performance of stainless steel continuous oil pipes. As the pressure increases, the pipes must withstand greater forces, which can lead to stress and potential failure. Stainless steel has excellent mechanical properties, but it is not invincible. According to the American Society of Mechanical Engineers (ASME), the pressure rating of stainless steel pipes decreases as the temperature increases, necessitating careful consideration of both factors when designing systems.

For instance, at ambient temperatures, a stainless steel pipe may be rated for a certain pressure, but as the temperature rises, the allowable pressure rating can drop significantly. This interplay between temperature and pressure highlights the importance of adhering to design codes and standards to prevent catastrophic failures. Engineers must conduct thorough analyses to ensure that the pipes will perform safely under the expected operating conditions.

Implications for Safety and Efficiency

Understanding the effects of temperature and pressure on stainless steel continuous oil pipes is not just an academic exercise; it has real-world implications for safety and efficiency. Failures in oil pipelines can lead to disastrous environmental consequences, including spills and contamination. According to the Pipeline and Hazardous Materials Safety Administration (PHMSA), pipeline incidents can cost companies millions of dollars in repairs and fines, not to mention the damage to their reputation.

By proactively monitoring temperature and pressure, operators can implement maintenance schedules and replace components before failures occur. Additionally, investing in advanced materials and technologies, such as corrosion-resistant coatings and advanced monitoring systems, can enhance the longevity and reliability of stainless steel pipes. Ultimately, prioritizing these factors can lead to safer, more efficient oil transportation systems.

Temperature and pressure are critical factors that significantly influence the performance of stainless steel continuous oil pipes. Understanding their effects is essential for ensuring the safety and efficiency of oil transportation systems. By closely monitoring these parameters and implementing effective maintenance strategies, operators can mitigate risks and prolong the lifespan of their infrastructure. As the oil and gas industry continues to evolve, staying informed about these critical factors will be paramount for all stakeholders involved.

Contact Us